If you’re considering a flooring upgrade for your Melbourne home or business, epoxy flooring is a standout choice that combines functionality and style in a unique way. Known for its robustness and sleek finish, epoxy flooring has become a popular choice across various industries and residential areas. This extensive guide delves deep into the many facets of epoxy flooring, helping you understand everything from its basic definition to detailed installation processes, maintenance tips, and cost considerations in the context of Melbourne, Australia.

1. What is Epoxy Flooring?

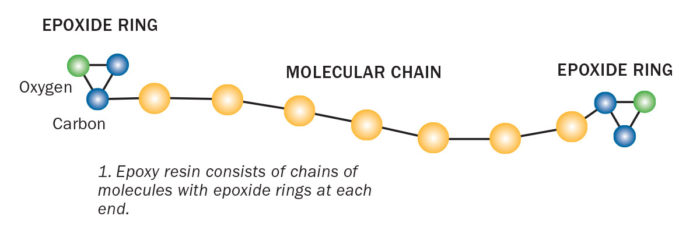

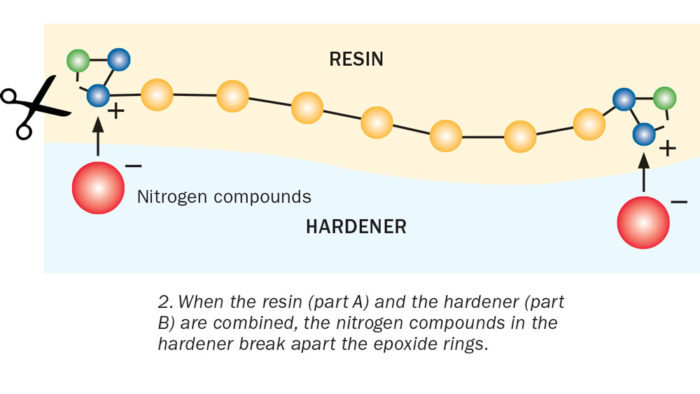

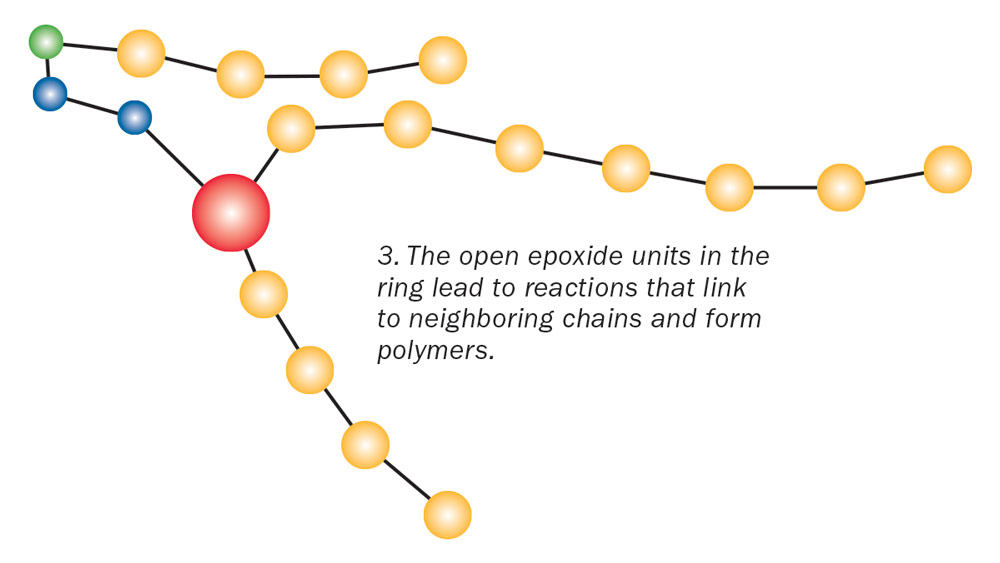

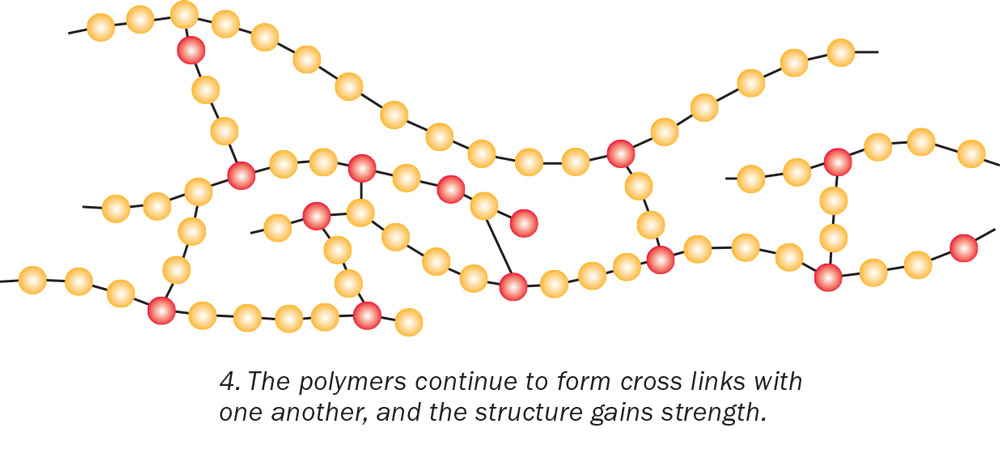

Epoxy flooring is more than just a protective surface; it’s a resilient and versatile flooring system that consists of two main components: resins and hardeners. So, when these two components are mixed, they react chemically to form a rigid plastic material, which is then applied over a substrate, usually concrete. This mixture cures to form a smooth, durable, and resistant flooring surface that adheres permanently to its base layer.

1.1Properties of Epoxy Resin

The resin component in epoxy flooring is a clear or colored viscous compound that can be formulated to offer various performance features, such as enhanced strength, resistance to degradation from chemicals, and UV stability. This adaptability makes epoxy flooring an excellent choice for both aesthetic and practical applications.

1.2 Hardener Characteristics

The hardener acts as a catalyst in the epoxy mixture and is crucial for curing the resin into a solid form. This component determines the rate of curing and can be adjusted according to the specific needs of the installation, such as ambient temperature conditions.

1.3 Chemical Reaction between Epoxy and Hardener

When you mix epoxy resin with hardener, you start a chemical reaction that transforms the combined liquid ingredients into a solid. As it cures, epoxy moves from a liquid state through a gel state, and finally reaches a solid state. Once in the solid state it cannot be uncured.

See below the schematic of chemical reaction between epoxy resin and hardener:

Source: Fine Woodworking Magazine

2. What is Epoxy Flooring Used For?

Epoxy flooring is valued in Melbourne for its versatility, durability, and aesthetic appeal, making it a popular choice for a wide range of applications across various industries and settings. Epoxy flooring is commonly used in Melbourne for commercial, industrial, and residential applications. Here are some common uses:

2.1 Commercial and Industrial Spaces

Epoxy flooring is popular in warehouses, factories, and commercial buildings due to its durability, resistance to heavy foot and vehicle traffic, and its ability to withstand chemicals and spills. It provides a seamless and easy-to-clean surface, making it ideal for environments where cleanliness and hygiene are important.

Read More:

2.2 Retail Stores and Showrooms

Many retail stores and showrooms in Melbourne opt for epoxy flooring because it offers a sleek, modern look that can enhance the appearance of the space. It’s also highly customizable, allowing businesses to incorporate logos, patterns, or specific colors into the flooring.

2.3 Garages and Automotive Workshops

Homeowners in Melbourne often choose epoxy flooring for their garages because it creates a durable and attractive surface that can withstand the weight of vehicles, resist stains from oil and grease, and is easy to clean.

Read More:

2.4 Healthcare Facilities

Hospitals, clinics, and other healthcare facilities in Melbourne utilize epoxy flooring in areas such as operating rooms, laboratories, and patient rooms due to its hygienic properties and resistance to bacteria and germs.

2.5 Food and Beverage Industry

Epoxy flooring is widely used in restaurants, cafes, commercial kitchens, and food processing plants in Melbourne because it meets strict health and safety standards, is resistant to stains and spills, and can withstand frequent cleaning with harsh chemicals.

Read More:

2.6 Residential Applications

In residential settings, epoxy flooring is commonly used in basements, kitchens, bathrooms, and living areas. It provides a durable and waterproof surface that is easy to maintain and can be customized to match the homeowner’s aesthetic preferences.

3. Process of Installing Epoxy Flooring

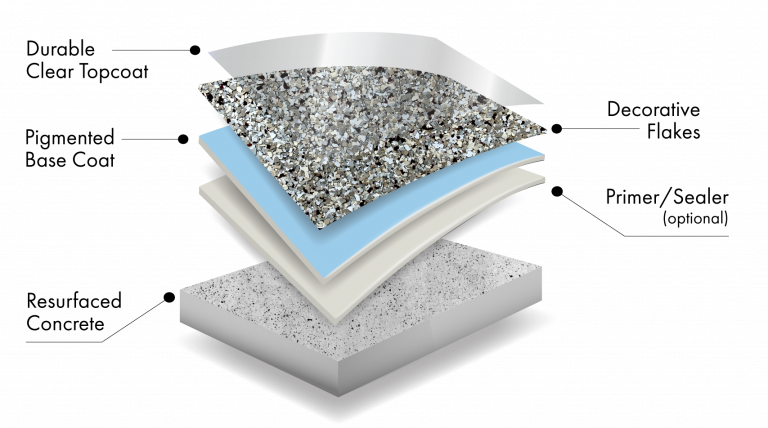

The installation of epoxy flooring is a precise process that involves several critical steps to ensure a successful application:

3.1 Initial Floor Preparation

The first step involves preparing the substrate by cleaning the surface thoroughly and repairing any cracks, holes, or irregularities. This may involve grinding, shot-blasting, or scarifying the concrete to create a profile suitable for epoxy adhesion.

3.2 Primer and Base Coat Application

A primer is applied to enhance the bond between the concrete and the epoxy. Following the primer, a base coat of epoxy is applied. This layer is crucial as it forms the foundation for the rest of the flooring system.

3.3 Applying the Epoxy

After the base coat, additional layers of epoxy or decorative elements are applied. The specific application method can vary, including troweling, rolling, or squeegeeing, depending on the type of epoxy being used and the desired finish.

3.4 Curing and Sealing

The final step in the installation process involves curing, which can take several days. After curing, a sealant may be applied to protect the floor and enhance its aesthetic qualities.

Source: DIAMOND GARAGE SOLUTIONS

4. Types of Epoxy Flooring Available

Depending on your specific needs, there are several types of epoxy flooring systems available:

4.1 Self-Leveling Epoxy Floors

This type is perfect for correcting uneven surfaces and providing a smooth finish. It’s particularly well-suited for commercial and industrial buildings, where floors must withstand heavy traffic or large equipment.

4.2 Epoxy Mortar Floors

Comprising 100% solid epoxies mixed with graded sand or quartz sand, epoxy mortar floors are the epitome of durability. They are frequently used in heavy-duty industrial settings and can help repair cracks before a floor is finished.

4.3 Decorative Epoxy Floors

These floors incorporate colored chips or metallic powders to create a decorative look that doesn’t compromise on the inherent benefits of epoxy. Ideal for showrooms, retail spaces, and residential living areas, decorative epoxy can be tailored to match any interior design.

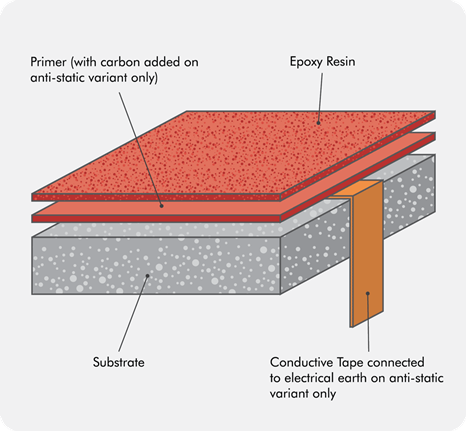

4.4 Anti-Static Epoxy Floors (ESD Resistant Floors)

For environments where static electricity poses a risk, such as in electronic manufacturing or laboratories, anti-static epoxy floors can be a crucial feature. These floors reduce static hazards, protecting sensitive equipment and enhancing workplace safety.

Source: Flowcrete

4.5 Quartz-Filled Epoxy Floors

Combining the durability of epoxy with the aesthetic appeal of colored quartz, quartz-filled epoxy floors offer a visually striking and functional flooring solution that is perfect for public spaces, schools, and healthcare facilities.

5. Benefits of Epoxy Flooring in Melbourne

In Melbourne’s dynamic climate and bustling urban environment, flooring needs to be both visually appealing and highly durable. Epoxy flooring meets these requirements and offers several compelling advantages. See below top epoxy flooring benefits for properties in Melbourne:

5.1 Aesthetic Versatility

Epoxy comes in an array of finishes, from high-gloss options to subtle matte looks, allowing it to easily mimic the appearance of more expensive flooring options like terrazzo or marble.

5.2 Improved Safety

By integrating non-slip additives, epoxy flooring can be made safe for areas prone to wet conditions or where there’s heavy foot traffic, making it ideal for public venues, commercial kitchens, and hospitals.

5.3 Resistance to Wear and Tear

The toughness of epoxy flooring makes it resistant to impact, stains, and chemical spills, which is perfect for industrial environments or places with heavy machinery.

5.4 Seamless and Hygienic

The continuous surface of epoxy floors leaves no joints or seams where dirt and bacteria might accumulate, simplifying cleaning and maintenance efforts.

5.5 Longevity and Cost-Effectiveness

Epoxy flooring is a long-term investment due to its durability and minimal need for repairs or replacements, translating into lower lifecycle costs compared to other flooring options.

6. Disadvantages of Epoxy Flooring and Strategies for Mitigation

Epoxy flooring, known for its durability and design versatility, comes with certain drawbacks that can be addressed to enhance its overall appeal. Below are the key disadvantages associated with epoxy flooring along with strategies to convert them into advantages:

6.1 Slipperiness When Wet

– Epoxy floors tend to become slippery when wet, posing a safety risk.

– Solution: Incorporate anti-slip additives during installation to improve traction.

6.2 Complex Installation Process

– Professional expertise is essential for proper epoxy floor installation to prevent issues like bubbling or peeling.

– Opportunity: Offer professional installation services to ensure a flawless finish and customer satisfaction.

6.3 Temperature and Humidity Sensitivity

– Temperature and humidity fluctuations during installation can impact the final outcome.

– Approach: Control the environment during installation or target regions with stable climates for optimal results.

6.4 Extended Curing Time

– Epoxy floors require a prolonged curing period post-installation.

– Strategy: Inform customers upfront about curing time and schedule installations during non-operational hours to minimize disruptions.

6.5 Hardness Leading to Discomfort

– The hardness of epoxy flooring may cause discomfort in areas where individuals stand for extended periods.

– Resolution: Use anti-fatigue mats in standing areas to enhance comfort levels.

6.6 Challenges in Repairing Damages

– Repairing small cracks or chips in epoxy flooring can be arduous without replacing the entire floor.

– Approach: Provide a comprehensive warranty or repair service as a unique selling point.

7. Maintenance Tips for Epoxy Flooring

To maximize the lifespan and appearance of your epoxy flooring, regular maintenance is essential. Here are some practical tips:

7.1 Routine Cleaning

Regular sweeping and occasional mopping with mild cleaners are sufficient to keep the floor looking new. Avoid abrasive tools and harsh chemicals.

7.2 Dealing with Spills

Immediate action on spills will prevent potential staining and slipping hazards.

7.3 Periodic Checks

Regularly check for any signs of wear or damage, such as scratches or lifting, and address these issues promptly to maintain the integrity of the flooring.

8. Cost Considerations for Epoxy Flooring in Melbourne

The cost of epoxy flooring in Melbourne varies based on several factors, including the type of epoxy, the condition of the existing floor, the total area to be covered, and the complexity of the design chosen. Basic epoxy flooring installations can start from around $30 to $35 per square meter, while more elaborate designs and high-performance coatings may cost $80 per square meter or more.

9. Conclusion: Enhance Your Space with Epoxy Flooring

Choosing epoxy flooring is an excellent way to enhance the functionality and aesthetic appeal of your space. Whether you are updating a commercial property or revamping your home, epoxy offers a durable, attractive, and cost-effective solution. With its wide range of finishes and styles, easy maintenance, and strong performance under tough conditions, epoxy flooring is an investment that will transform and enrich any Melbourne property.

By understanding the unique properties, types, and benefits of epoxy flooring, you can make an informed decision that aligns with your needs and expectations. Embrace the change that epoxy flooring can bring to your space and enjoy its lasting beauty and resilience.

0 Comments